NTW’s new Energy Storage Lab (located in Room 106 on the first floor) has started its’ buildout with the installation of a large environmental testing chamber (ENV01). While the remainder of the lab will continue to be facilitized over the coming months under the direction of Professors Jung Hyun Kim and Vicky Doan-Nguyen, the environmental chamber is now available for …

NTW Lab Management System Adds Cleanroom Displays

NTW’s Lab Management System (or “swipe” system) has been upgraded to include 43″ display monitors in each bay of the cleanroom. The display in each bay contains some schedule details (current, previous and next user) for each tool located in that bay as well as a list of tools currently in use throughout the rest of the cleanroom. Some displays …

MICA Lab Adds Low Temperature Probe Station

NTW’s Mid-Infrared Characterization and Application (MICA) lab (located in Room 117) continues its buildout with the addition of a Lakeshore CRX6.5k cryogenic probe station (tool code PRB07) to provide low temperature device probing capability. Cooled by a closed cycle helium compressor the probe station supports measurements between 6.5K and 350K. The system is configured with four Triax probe arms and …

Device Packing Capability Added with Flip Chip Bonder Installation

Nanotech West Labs has recently expanded its device packaging capabilities with the installation of a SET FC150 (tool code BND04) “flip chip” bonder. Designed to enable precision aligned chip or die bonding, the machine is configured with a low-contact force (up to 4N) solder reflow arm (SRA) with 2″ chucks as well as a laser leveling system. A split field …

New Lapping and Polishing Capabilities at Nanotech West

Nanotech West now offers the capability to thin samples down and polish samples smooth using the new PM4 lapper and PM5 polisher. The last polishing step offers a contamination-free colloidal silica environment for nanometer-scale final roughness. These processes would be excellent for preparing samples for bonding, eliminating damage after ion implantation, damascene-style metal patterning, optical surface preparations, creating thin layers …

Nanotech West Obtains Optical Profilometer

Nanotech West announces the availability of a Zeta-20 optical profilometer, located in Bay 3 of the cleanroom. The tool (tool code INS09) is capable of the 3D imaging of surfaces with a z resolution of ~15 nm, as well as serving as an excellent optical microscope. Its purchase was enabled by the Ohio Sensor and Semiconductor Innovation Platform (OSSIP) program, …

Nanotech West and NanoSystems Labs Announce Annual Retraining Schedule

Nanotech West and the NanoSystems Labs are announcing their Annual Safety Retraining Program (ASRP) schedule. The sessions will start the third week of May, immediately after IMR Materials Week. Twenty-three sessions are currently scheduled, both in campus and at Nanotech West. All Columbus-area users are required to attend a session. As before: If in the past you have attended a …

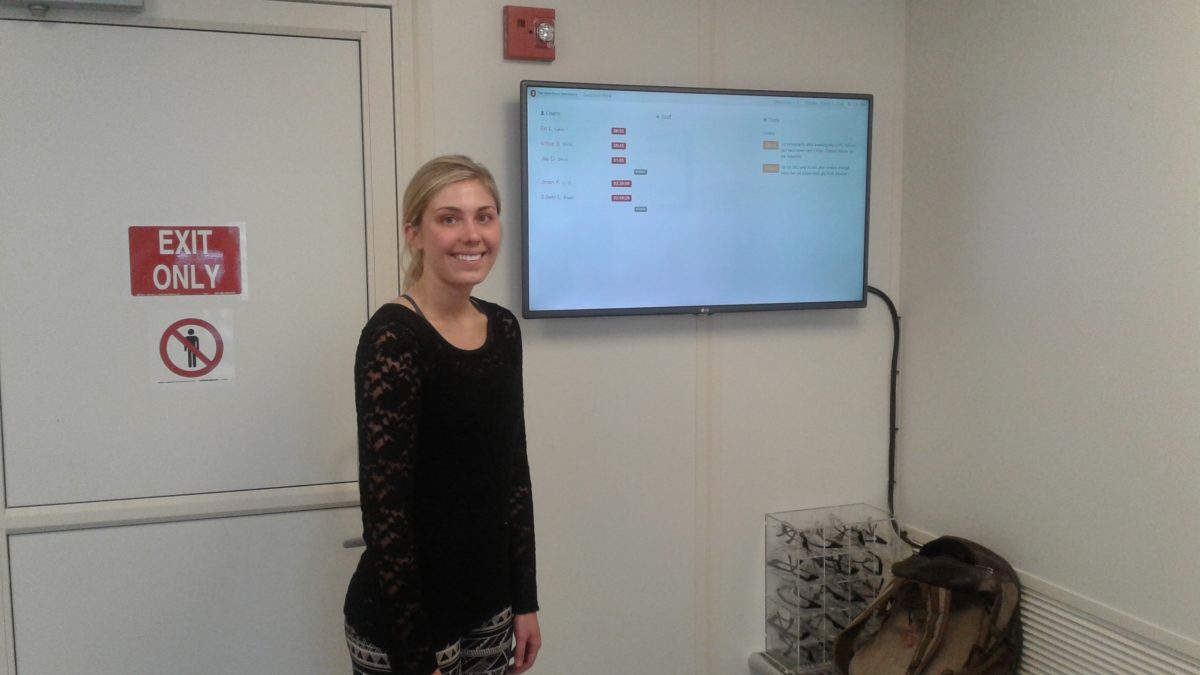

Nanotech West Adds Information Display

A new, large flat panel display is now located in the pre-togging room of the Nanotech West cleanroom. The display continuously pulls information from the NTW central databases and displays information on who is currently in the lab, what tools they are using, and what tools are down or partially operational and their status. In the future it will also …

Nanotech West Staff Member Judges UA HS Science Fair

Nanotech West staff member (and IMR Member of the Technical Staff) Aimee Price (L) was a judge in the Upper Arlington High School Science Fair last week. In judging, she happened to run into Prof. Wendy Panero (R), whose daughter, Karen Snyder (Center), was presenting her work on “The Association Between Local Weather and Influenza Hospitalization in Emerging Infections States”. …

Tube Furnace Now Available with Forming Gas

Forming gas (5% H2 in N2) annealing is now available on furnace tube TUB01 for samples from small pieces up to 150 mm wafers and temperatures up to 790°C. Please contact Paul Steffen at steffen.8@osu.edu for details and to schedule processing. The furnace tube has been converted from LPCVD polysilicon deposition to forming gas anneals. The LPCVD poly has been …