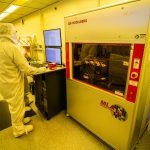

Nanotech West Laboratory has substantially expanded its lithography capabilities with the recent installation of an advanced maskless aligner system.

The state-of-the-art maskless technology of the recently acquired MLA150, from Heidelberg Instruments, allows researchers to leave traditional photomasks at the cleanroom door. The photolithography system is ideal for rapid prototyping due to its ease of use, high-speed performance and non-contact exposure.

“Researchers can now go from idea to design to finished product seamlessly,” said Dave Hollingshead, a senior research associate at Nanotech West Lab, which is operated by the Institute for Materials and Manufacturing Research (IMR). “This greatly speeds up the development of all the chips, sensors and devices that we make here every day.”

The MLA150 is capable of patterning features as small as 0.6 µm and includes the options for grayscale patterning and backside alignment. Samples up to 150mm x 150mm can be exposed. Potential applications include 2D materials, opto-electronics, high-power transistors, and infrared detectors.

In contrast to a traditional mask aligner, this system exposes electronic patterns directly onto a sample quickly, with zero contact, and without the need to produce a physical mask. The system also allows faster alignment and inspection, with an overview camera and real-time autofocus.

Sanjay Krishna, George R. Smith Chair in Engineering, said he expects the new tool to be an asset in his research on infrared detectors and focal plane arrays, and have a broader impact on the advancement of materials research at The Ohio State University.

“The fact that we can make extremely small feature sizes, and do this rapidly, helps us materialize our ideas into rapid prototypes,” he said. “This will not only help my research group at the KIND Laboratory, but will help the whole IMR community.”

The intuitive design and software is expected to allow for a better experience for users, from professional researchers in academia to students to industry researchers.

The addition of the new maskless aligner system gives the Nanotech West Lab on West Campus a range of capabilities, from contact aligners to electron-beam lithography tools and the new direct laser writer, said Aimee Price, a senior research associate at Nanotech West Lab.

“The new system is going to extend our capabilities and range of lithography tools for our researchers,” she said. “It is really important for the breadth and mix of users that we have here at Ohio State, so we are really excited for the new system.”

Visit the Heidelberg Instruments website for more information about the system. Visit the Nanotech West site to learn more about the lab and instrument availability.

Reposted with permission from IMR

For more information, please contact Dave Hollingshead (hollingshead.19@osu.edu) or another NTW staff member.