Figure 1: X-Celeprint MTP-1003 (XFR01)

The X-Celeprint Micro-Transfer Printing equipment (XFR01) as shown in Figure 1 is now available for use in the cleanroom.

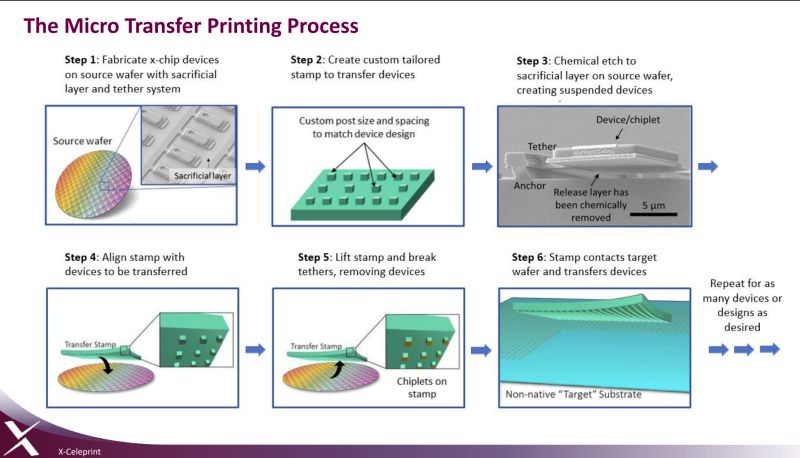

Micro-transfer printing (MTP) is a technique that enables the assembly of diverse semiconductor devices onto various substrates. These devices are fabricated on their native substrates, such as silicon, gallium arsenide, or indium phosphide, using conventional methods. Then, they are released from their substrates by etching a sacrificial layer, leaving them attached by thin metal tethers. Using Van der Waals forces, microstructured elastomer stamps made of elastomer Polydimethylsiloxane (PDMS) then pick up the devices by pressing on them and breaking the tethers. The stamps place the devices on another substrate, such as a silicon chip, a plastic film, or a glass plate (Figure 2). By doing this, new and complex systems are created by combining different devices on the same substrate. For example, PDMS stamps can make a micro-LED display by transferring tiny light-emitting devices onto a glass plate.

MTP has several advantages over other methods of heterogeneous integration, such as flip-chip bonding or direct epitaxial growth. It allows the re-use of the growth substrates, which can reduce the cost and environmental impact of the process. It also decouples the fabrication and usage of high-performance materials, which can increase the design flexibility and compatibility of the devices. It achieves high placement accuracy, high process yield, and high throughput, which improves the performance and reliability of the systems. MTP is a promising technology for applications such as flexible electronics, sensors, photovoltaics, and micro-LED displays.

XFR01, X-Celeprint model MTP-1003, has the following capabilities:

- Transfer devices as small as 3 x 3 µm x 200 nm to larger than 1 x 1 mm

- Devices printed with a spacing as little as to 2 µm

- Effective 100% yields

- Greater than 99.9% accuracy per print cycle

- High throughput

- Four motorized axes

For more information about XFR01 or training, contact: murkute.1@osu.edu

Figure 2. Step-by-step micro-transfer printing (MTP) processes using XFR01